Secondary Processing

Secondary Processing

Tumbling

KVM delivers in-line tumbling systems as well as offline systems. The KVM Tumbling Systems are characterized by:

- High output

- Simple operation

- Easy product change

- Automatic quality control

The systems handle all types of pavers, big blocks and split faced products. Products are tumbled in heavy duty drums with rubber lining. KVM Inline Tumbling Systems are adapted to handle 24 hours old products.

The system can tumble and cube up to 350 m2 per hour. Inline Systems can tumble products directly from an Inline splitting system, giving a unique product with minimal need for operators.

The KVM offline system gives a high product quality and makes it possible to mix pavers in up to four different colors. The off-line system is built around a KVM cuber and automatic quality sorting.

The KVM Tumbling Systems are all operated by a PLC control system backed up by our 24/7 online service system.

Splitting

Splitting of concrete blocks is a popular refinement method. KVM splitting machines produce split concrete blocks that hardly can be distinguished from natural stones. A splitting machine can be integrated inline, or it can also be operated offline as a separate unit.

The blocks are transferred to the splitter table by means of the steel table with double pushing device. The upper knife which is driven by a hydraulic cylinder moves downwards. Just before touching the blocks, the upper knife is stopped by a mechanical stop and the lower knife moves upwards. The split takes place bottom-up. The splitter is driven by hydraulic. The splitter can also be fitted with additional side knives for a four sided splitting and with y shaped knives for edged products.

The splitter can also be fitted with additional side knives for a four sided splitting and with y shaped knives for edged products.

The KVM splitting lines are operated from a PLC control system backed up by our 24/7 online service.

Washing

A KVM washing unit is used to expose the aggregate in the product surface of the fresh product. Fine particles of the aggregate materials as well as cement residue is removed by in a spray washing process. With this the visual effect of special materials in the face material is emphasized.

The washing system can be adjusted in for different settings. With the KVM soft washing the washing depth is 2-3mm and with the hardwash setting the washing depth is 4-8mm.

- A KVM washing unit is equipped with:

- adjustable nozzles

- adjustable settings for water pressure and flow

- high-pressure nozzle bars with oscillating movement of the nozzles

- low-pressure nozzle and rinsing water bar for removal of the cement residue

- air nozzles to blow off remaining water

- quick replace system of the single nozzles or the nozzle bar

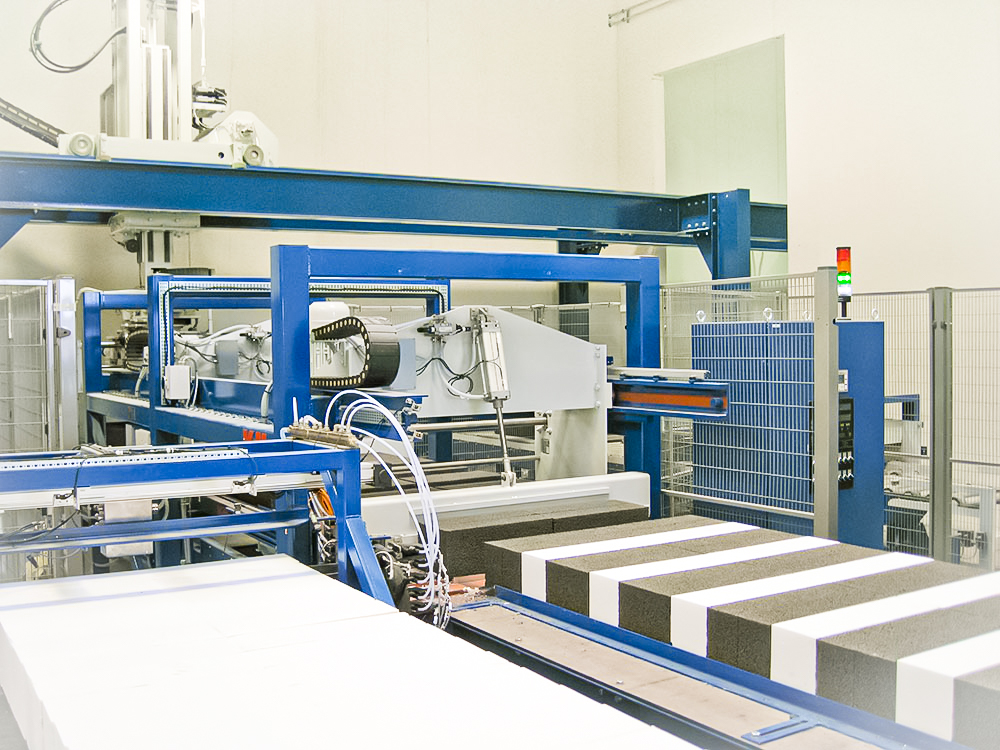

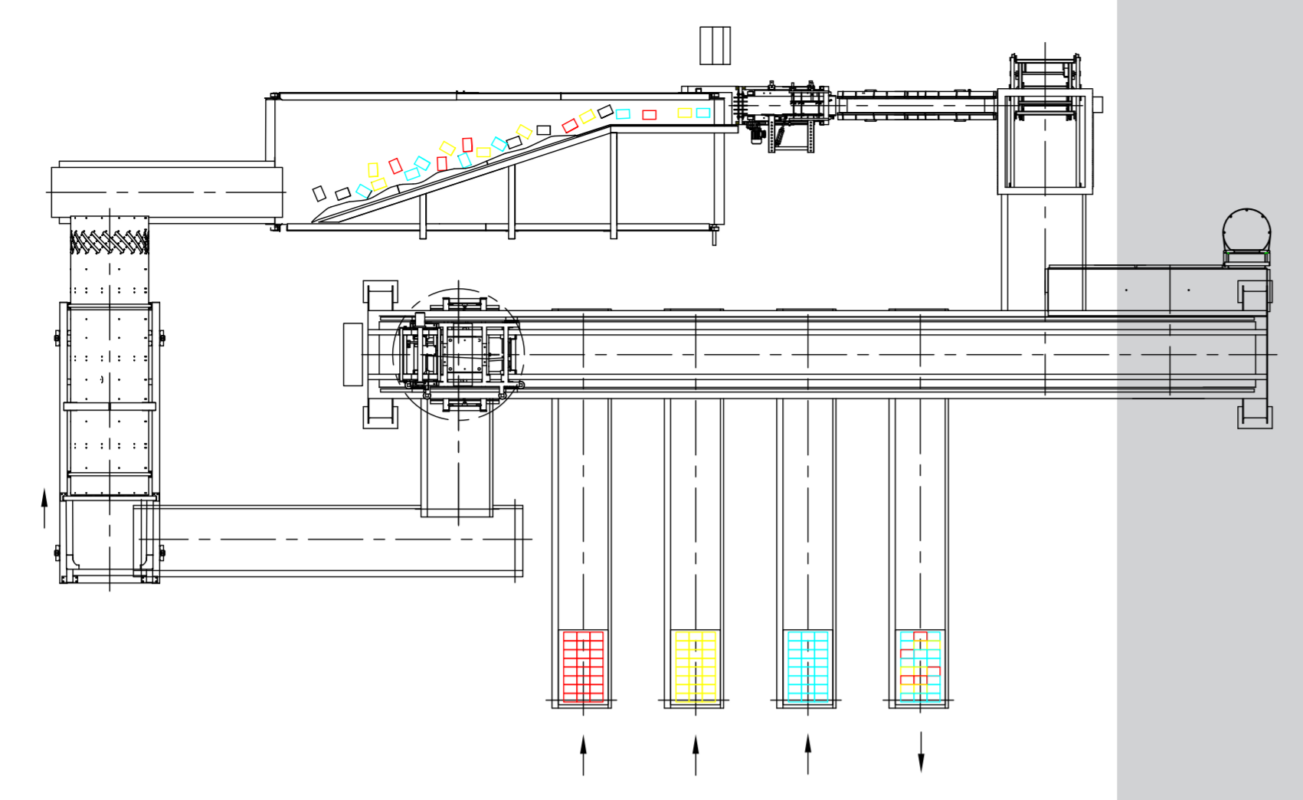

Insulation blocks

Insulated building blocks are produced in using two alternative methods.

- By inserting the insulating material into the blockmachine mould. An automatic robotic system inserts the insulating material into the mould before the blockmachine produces the rest of the block using lightweight concrete. This method has been used successfully for more than 50 years.

- A more modern method is to use the blockmachine to produce standard lightweight building blocks and glue two of these on both sides of the insulating material. This method doubles the production capacity and ensures a uniform product quality and improves the insulating capacity of the blocks. This method makes it possible to use alternative insulating material and alternative block materials.

Ventilation bit dispenser

Efflorescence, the ugly white areas on concrete product surfaces, has always been a problem for producers of slabs.

The KVM Ventilation Bit Dispenser is an effective weapon against this. It automatically places a plastic Bit in each corner of the product letting air between each layer of stacked product. This let moisture away from the product surface and thus reduce the efflorescence. The bits also protect high value slabs from transport damage. The Bit Dispenser is placed on the dry side between the curing area and cuber.

The unit can place a variable number of bits on the product. The Bit Dispenser is controlled from a touch screen and is programmable for different product types.

The Ventilation Bit Dispenser is an independent unit that can be installed in new plants as well as be integrated into existing ones.

Ventilation sand dosing

Efflorescence, white areas on product surfaces, has for years been a problem for producers who make slabs and pavers. Customers do not like the white spots on the surface. Especially on black and darker coloured products. This is the reason for receiving many complaints from the end-user. Efflorescence is caused by a combination of circumstances: soluble salts in the material, moisture to dissolve the salts, and vapour transmission or hydrostatic pressure that moves the solution toward the surface. Water in moist, hardened concrete dissolves soluble salts. This salt-water solution migrates to the surface by vapour transmission or hydraulic pressure where the water evaporates, leaving the salt deposit at the surface. Particularly temperature, humidity and wind affect efflorescence.

In the summer, even after long periods of rain, moisture evaporates so quickly that comparatively small amounts of salt are brought to the surface. The new KVM Ventilation Sand Feeder is an effective weapon against the problem. It places an adjustable amount of sand between the layers of products in the stack, and thus reduces the efflorescence. The unit can be used for all types and sizes of concrete products.

The sand is dosed automatically by vibration feeding on the products before cubing.